Gun

Gun

The Remington XP-100 (from eXperimental Pistol number 100) is a bolt action pistol produced by Remington Arms from 1963 to 1998. The XP-100 was one of the first handguns designed for long range shooting, and introduced the .221 Remington Fireball (often called .221 Fireball), which is still the fastest handgun cartridge ever produced by a major ammunition maker. The XP-100 was noted for its accuracy and is still competitive today in the sport of handgun varminting, which it helped create.

Overview

The XP-100 was based on Remington’s short action bolt action carbine, the Remington Model 40X, which influenced the later Remington Model 600 rifle. The XP-100 was initially introduced with a 10¾” barrel set into a nylon stock with an unusual center-mounted grip. Chambered in .222 Remington in early prototypes, the short barrel produced significant noise and muzzle flash. Subsequently the case was shortened to reduce powder capacity to a volume more suited to the shorter barrel of a pistol. The resulting cartridge, the .221 Fireball, produced factory loaded velocities of over 825 m/s (2700 ft/s) from the short barrel, and accuracy rivaling the parent .222 Remington, one of the most accurate cartridges made.

All but the XP-100R model were single shot designs, while the XP-100R had a small internal magazine (holding four rounds), similar to most bolt action rifles. The R model – for “repeater” – was made 1991-1997 in .223 Rem., .250 Savage, 7mm-08 Rem., .308 Win., .35 Rem., and 350 Rem. Mag. It was reintroduced in 1998, this time without sights, in .223 Rem., .22-250 Rem., .260 Rem., and .35 Rem.

Model History

The XP-100 went through a number of changes during its production run, and many variations were only available through the Remington Custom shop. The most significant changes in the later versions were to barrel length, which went to 14½”, and the grip location, which was moved to the rear of the stock. The calibers changed; with the elimination of the original 10¾” barrel, the reduced powder capacity was no longer such a requirement, and the chamberings switched to standard commercial rifle cartridges. By the time the XP-100 was discontinued, it faced stiff competition from other bolt-action pistols such as the Savage Striker as well as the versatile Thompson Center Arms break-action Contender.

Model Production by Year

- XP-100 (1963-1985)

- XP-100 Varmint Special (1986-1992)

- XP-100 Silhouette (1980-1997)

- XP-100 Hunter (1993-1994)

- XP-100 Custom (1986-1997)

- XP-100R (1998)

- XR-100 (2005-Present)

Caliber Production by Year

- .221 Remington Fireball (1963-1985)

- 7 mm BR Remington (1980-1985)

- .223 Remington (1986-1997), (2005-Present in XR-100)

- .35 Remington (1986-1997)

- .250 Savage (1990-1992) Custom Shop only

- 6 mm BR Remington (1990-1992) Custom Shop only

- .22-250 Remington (1992-1994) Custom Shop only, (2005-Present in XR-100)

- .308 Winchester (1992-1994) Custom Shop only

- 7 mm-08 Remington (1993-1994)

- .204 Ruger (2005-Present in XR-100)

Current Production

The XP-100 action was used as the basis for a new single-shot rifle from Remington called the XR-100 Rangemaster.

While the XP-100 has disappeared from Remington’s lineup (Remington is primarily a maker of rifles and shotguns), the .221 Fireball remains in production. The Model 700 rifle has been available since 2002 in a .221 Fireball chambering; while it lacks the velocity attainable with the vastly more popular .223 Remington, the short .221 Fireball delivers most of the performance with far less noise and flash.

The Sass

The M82, standardized by the US Military as the M107, is a recoil-operated, semi-automatic anti-materiel rifle developed by the American Barrett Firearms Manufacturing company. It is used by many units and armies around the world. Despite its designation as an anti-materiel rifle, it is used by some armed forces as an anti-personnel sniper rifle. It is also called the Light Fifty for its .50 BMG (12.7×99mm NATO) chambering. The weapon is found in two variants, the original M82A1 (and A3) and the bullpup M82A2. The M82A2 is no longer manufactured, though the XM500 can be seen as its successor.

Overview

Barrett Firearms Manufacturing was founded by Ronnie Barrett for the sole purpose of building semi-automatic rifles chambered for the powerful 12.7×99mm NATO (.50 BMG) ammunition, originally developed for and used in M2 Browning machine guns. Barrett began his work in the early 1980s and the first working rifles were available in 1982, hence the designation M82. Barrett designed every single part of the weapon personally and then went on to market the weapon and mass-produce it out of his own pocket. He continued to develop his rifle through the 1980s, and developed the improved M82A1 rifle by 1986.

The first conventional military success was the sale of about 100 M82A1 rifles to the Swedish Army in 1989. Major success followed in 1990, when the United States armed forces purchased significant numbers of the M82A1 during operations Desert Shield and Desert Storm in Kuwait and Iraq. About 125 rifles were initially bought by the United States Marine Corps, and orders from the Army and Air Force soon followed. The M82A1 is known by the US military as the SASR – “Special Applications Scoped Rifle”, and it was and still is used as an anti-materiel rifle and explosive ordnance disposal (EOD) tool. The long effective range, over 1,800 metres (5,900 ft) (1.1 miles), along with high energy and availability of highly effective ammunition such as API and Raufoss Mk 211, allows for effective operations against targets like radar cabins, trucks, parked aircraft and the like. The M82 can also be used to defeat human targets from standoff range or against targets behind cover. However, anti-personnel use is not a major application for the M82. There is a widespread misconception that a number of treaties have banned use of the .50 BMG against human targets.

Technical Description

The M82 is a short recoil semi-automatic firearm. When the gun is fired, the barrel initially recoils for a short distance (about 1 in or 25 mm), while being securely locked by the rotating bolt. After the short travel, a post on the bolt engaged in the curved cam track in the receiver turns the bolt to unlock it from the barrel. As soon as the bolt unlocks, the accelerator arm strikes it back, transferring part of the recoil energy of the barrel to the bolt to achieve reliable cycling. Then the barrel is stopped and the bolt continues back, to extract and eject a spent case. On its return stroke, the bolt strips the fresh cartridge from the box magazine and feeds it into the chamber and finally locks itself to the barrel. The striker is also cocked on the return stroke of the bolt. The gun is fed from a large detachable box magazine holding up to 10 rounds, although a rare 12-round magazine was developed for use during Operation Desert Storm in 1991.

The receiver is made from two parts (upper and lower), stamped from sheet steel and connected by cross-pins. The heavy barrel is fluted to improve heat dissipation and save weight, and fitted with a large and effective reactive muzzle brake. On the earlier models the muzzle brakes had a round cross-section; later M82 rifles are equipped with two-chamber brakes of rectangular cross-section.

M82A1 rifles are fitted with scope mount and folding backup iron sights, should the glass scope break. The U.S. military M82 rifles are often equipped with Leupold Mark 4 telescopic sights. The M82A1M (USMC M82A3) rifles have long Picatinny accessory rails mounted and US Optics telescopic sights. Every M82 rifle is equipped with a folding carrying handle and a folding bipod (both are detachable on the M82A3). The M82A3 is also fitted with a detachable rear monopod under the butt. The buttpad is fitted with a soft recoil pad to further decrease the felt recoil. M82A1 and M82A3 rifles could be mounted on the M3 or M122 infantry tripods (originally intended for machine guns) or on vehicles using the special Barrett soft-mount. The M82A1 can be fitted with a carry sling but according to those who carried it in the field, the M82 is too uncomfortable to be carried on a sling due to its excessive length and weight. It is usually carried in a special carry soft or hard case.

The M82A2 differed from M82A1 mostly in its configuration – the pistol grip along with trigger was placed ahead of the magazine, and the buttpad placed below the receiver, just after the magazine. An additional forward grip was added below the receiver, and the scope mount moved forward.

The maximum effective range of the M107 is 1,830 metres (2,000 yd). The maximum range of this weapon (specifically the M107 variant) is 4,000 metres (4,400 yd), as quoted in the owner’s manual. Fifty caliber (and larger) rounds have the potential to travel great distances if fired in an artillery-like fashion, necessitating the observance of large safety margins when firing on a range.

The Sass

The Model 1200 pump-action shotguns that are manufactured by the Winchester-Western Division of Olin Corporation. It was produced in 12-, 16- and 20-gauge. The military version of the 1200 has the ability to have a bayonet fixed on the end of the barrel to be used in close quarter combat. It is a takedown type shotgun which means it has the capability of being taken apart for easy transportation and storage.

History

The Winchester Model 1200 was introduced in 1964 as a low-cost replacement for the venerable Model 12. A small number of these weapons were acquired by the United States Army in 1968 and 1969. The military style Model 1200 was essentially the same weapon as the civilian version, except it had a ventilated handguard, sling swivels, and a bayonet lug.

Description

The Winchester Model 1200 came in barrel lengths of 30-inch, and 28-inch with a fixed choke or the Win-choke screw in choke tubes system and is a 12, 16, or 20-gauge, manually operated, slide action shotgun. The slide action, also known as a pump-action, means that the shotgun has a moving bolt system which is operated by a “wooden or composite slide called the fore-end”. The fore-end is located on the underside of the barrel and moves front to back. The weapon can hold a maximum of five rounds total with four in the tubular magazine and one in the chamber. It has a hammerless action which means that there is no external hammer spur. There is only a firing pin which strikes the primer on the shell to ignite the powder in the round. The Model 1200 is a takedown type of shotgun; it can be taken apart for easy storage and transportation.

The Model 1200 was the first shotgun to utilize a rotary bolt with four locking lugs secured within the barrel extension. The 1200 was Winchester’s first shotgun to incorporate the company’s patented Winchoke system, a quick change tube to allow the easy replacement of chokes.

Bayonet

A bayonet could be attached to the front end of the barrel of the Military version of the Model 1200. The primary uses of the bayonet on the model 1200 are for close combat, guarding prisoners, and riot duty. The most commonly used bayonet with the Model 1200 was the M1917 bayonet. After World War I ended, there was a large surplus of the M-1917 bayonets because the Army decided to keep the M1903 Springfield as the standard issued rifle. The M-1917 bayonet did not fit the Springfield rifles so instead of just getting rid of them, the Army decided to make newer shotguns compatible with the bayonets.

The Sass

Heckler & Koch G3

The G3 is a 7.62×51mm NATO battle rifle developed in the 1950s by the German armament manufacturer Heckler & Koch GmbH (H&K) in collaboration with the Spanish state-owned design and development agency CETME (Centro de Estudios Técnicos de Materiales Especiales).

History

The origin of this rifle can be traced back to the final years of World War II when Mauser engineers at the Light Weapon Development Group (Abteilung 37) at Oberndorf am Neckar designed the MKb Gerät 06 (Maschinenkarabiner Gerät 06 or “machine carbine device 06”) prototype assault rifle chambered for the intermediate 7.92×33mm Kurz cartridge, first with the Gerät 06 model using a roller-locked short recoil mechanism originally adapted from the MG 42 machine gun but with a fixed barrel and conventional gas-actuated piston rod. It was realized that with careful attention to the mechanical ratios, the gas system could be omitted. The resultant weapon, the Gerät 06H (the “H” suffix is an abbreviation for halbverriegelt or “half-locked”) was assigned the designation StG 45(M) (Sturmgewehr 45(M) or assault rifle) but was not produced in any significant numbers and the war ended before the first production rifles were completed.

The German technicians involved in developing the StG 45(M) were taken to work in France at CEAM (Centre d’Etudes et d’Armement de Mulhouse). The StG 45(M) mechanism was modified by Ludwig Vorgrimler and Theodor Löffler at the Mulhouse facility between 1946 and 1949. Three versions were made, chambered in .30 Carbine, 7.92×33 mm Kurz as well as the experimental 7.65×35 mm French short cartridge developed by Cartoucherie de Valence in 1948. A 7.5×38 mm cartridge using a partial aluminium bullet was abandoned in 1947. Löffler’s design, designated the Carabine Mitrailleuse Modèle 1950, was retained for trials among 12 different prototypes designed by CEAM, MAC, and MAS. Engaged in the Indochina War and being the second NATO contributor, France canceled the adoption of these new weapons for financial reasons.

In 1950, Vorgrimler moved to Spain where he created the LV-50 rifle chambered for the Kurz cartridge and later, the proprietary 7.92×40 mm CETME M53 round. At this point, the rifle was renamed the Modelo 2. The Modelo 2 drew the attention of the West German Border Guards (Bundesgrenzschutz), who sought to re-equip the newly formed national defense forces. Not willing to accept a cartridge outside of the NATO specification, the Germans asked CETME to develop a 7.62×51 mm version of the rifle. The resulting CETME Model A was chambered for the 7.62×51 mm CETME cartridge which was identical in chamber dimensions but had a reduced-power load compared to the 7.62 mm NATO round. Further development of the rifle with input from H&K produced the CETME Model B which received several modifications, including the ability to fire from a closed bolt in both semi-automatic and automatic firing modes, a new perforated sheet metal handguard (the folding bipod had been the foregrip in previous models), improved ergonomics and a slightly longer barrel with a 22 mm rifle grenade launcher guide. In 1958, this rifle was accepted into service with the Spanish Army as the Modelo 58, using the 7.62×51 mm CETME round.

In 1956, the Bundesgrenzschutz canceled their planned procurement of the CETME rifles, adopting the Belgian-made FN FAL (G1) instead. However, the newly formed West German Army (Bundeswehr) now showed interest and soon purchased a number of CETME rifles (7.62×51 mm NATO chambering) for further testing. The CETME, known as the Automatisches Gewehr G3 according to German nomenclature, competed successfully against the Swiss SIG SG 510 (G2) and the American AR-10 (G4) to replace the previously favored G1 rifle. In January 1959, the Bundeswehr officially adopted the CETME proposal. The West German government wanted the G3 rifle to be produced under license in Germany; purchase of the G1 had previously fallen through over FN’s refusal to grant such a license. In the case of the G3, the Dutch firm Nederlandse Wapen en Munitiefabriek (NWM) held production and sales rights to the CETME design outside of Spain. To acquire production rights, the West German government offered NWM contracts to supply the German Air Force (Luftwaffe) with 20mm ammunition. Production of the G3 was then assigned to Rheinmetall and H&K. The latter company already had ties to CETME, and had worked to further optimize the CETME rifle for use with the full-power 7.62×51 mm NATO cartridge (as opposed to the downgraded CETME variant). In 1969, Rheinmetall gave up production rights to the G3 in exchange for H&K’s promise not to bid on MG 3 production. Later in 1977, the West German government ceded ownership of G3 production and sales rights exclusively to H&K.

Initial production G3 rifles differed substantially from more recent models; early rifles featured closed-type mechanical flip-up sights (with two apertures), a lightweight folding bipod, a stamped sheet steel handguard, a wooden buttstock (in fixed stock models) or a telescopic metal stock. The weapon was modernized during its service life (among other minor modifications it received new sights, a different flash suppressor, and a synthetic handguard and shoulder stock), resulting in the most recent production models, the G3A3 (with a fixed polymer stock) and the G3A4 (telescoping metal stock). The rifle proved successful in the export market, being adopted by the armed forces of over 40 countries. The G3 was and in some cases continues to be produced under license in: France (MAS), Greece (Hellenic Arms Industry), Iran (Defense Industries Organization), Luxembourg (Luxemburg Defense Technologie), Mexico, Myanmar, Norway (Kongsberg Våpenfabrikk), Pakistan (Pakistan Ordnance Factories), Portugal (FBP), Saudi Arabia, Sweden (FFV), Thailand, Turkey (MKEK) and the United Kingdom (Royal Ordnance).

Design Details

The G3A3 (A4) is a selective-fire automatic weapon that employs a roller-delayed blowback operating system. The two-piece bolt assembly consists of a breech (bolt head) and bolt carrier. The bolt is held in battery by two sliding cylindrical rollers that engage locking recesses in the barrel extension (popularly called a “trunnion”; BATF calls this a “mounting block”). The breech is opened when both rollers are compressed inward against camming surfaces driven by the rearward pressure of the expanding gases upon the bolt head. As the rollers move inward, recoil energy is transferred to the locking piece and bolt carrier which begin to withdraw while the bolt head slowly moves rearward in relation to the bolt carrier. As the bolt carrier clears the rollers, pressure in the bore drops to a safe level, the bolt head is caught by the bolt carrier and moves to the rear as one unit, continuing the operating cycle. The bolt also features an anti-bounce mechanism that prevents the bolt from bouncing off the barrel’s breech surface. The spring-powered claw extractor is also contained inside the bolt while the lever ejector is located inside the trigger housing (actuated by the recoiling bolt).

The rifle is hammer fired and has a trigger mechanism with a 3-position fire selector switch that is also the manual safety toggle that secures the weapon from accidentally discharging (fire selector in the “E” or “1” position – single fire mode (“Einzelfeuer”), “F” or “20” – automatic fire (“Feuerstoß”), “S” or “0” – weapon is safe (“Sicher”), trigger disabled mechanically). The weapon can be fitted with an optional 4-position safety/fire selector group illustrated with pictograms with an ambidextrous selector lever. The additional, fourth selector setting enables a 3-round burst mode of fire.

The firearm is equipped with iron sights that consist of a rotary rear drum and hooded front post. The rear sight, mechanically adjustable for both windage and elevation, has an open notch used to fire up to 100 m and three apertures used for: 200, 300 and 400 m. The receiver housing has recesses that work with HK clamp adapters used to mount day or night optics.

The rifled barrel (contains 4 right-hand grooves with a 305 mm twist rate) terminates with a slotted flash suppressor which can also be used to attach a bayonet or serve as an adapter for launching rifle grenades. From the G3A3 the barrel had polygonal rifling. The barrel chamber is fluted, which assists in the initial extraction of a spent cartridge casing (since the breech is opened under very high barrel pressure).

The G3A3 (A4) uses either steel (260 g) or aluminium (140 g) 20-round double-stacked straight box magazines, or a 50-round drum magazine. H&K developed a prototype plastic disposable magazine in the early 1960s, but it was not adopted as aluminum magazines were just as light and proved more durable, as well as easier to produce.

Standard accessories supplied with the rifle include: a detachable bipod (not included with rifles that have a perforated plastic handguard), sling, cleaning kit and a speed-loading device. Several types of bayonet are available for the G3, but with few exceptions they require an adapter to be inserted into the end of the cocking tube. The most common type features a 63/4 inch spear-point blade nearly identical with the M7 bayonet, but with a different grip because of its mounting above the barrel. The weapon can also mount a 40 mm HK79 under-barrel grenade launcher, blank firing adapter a straight blowback bolt (called a “PT” bolt, lacks rollers) used for firing 7.62×51 mm ammunition with plastic bullets, a conversion kit used for training with .22 Long Rifle ammunition and a sound suppressor (that uses standard ammunition).

The G3 is a modular weapon system. Its butt-stock, fore-stock and pistol-grip/fire-control assembly may be changed at will in a variety of configurations. Simple push-pins hold the components in place and removing them will allow the user to remove and replace parts rapidly.

The Sass

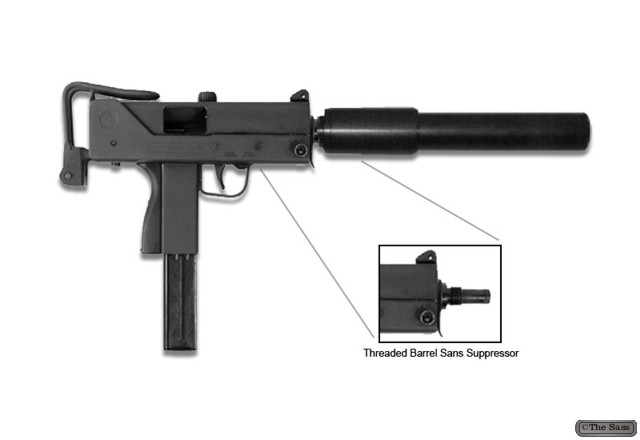

Ingram MAC-10

The MAC-10 (Military Armament Corporation Model 10, officially the M-10) is a compact, blowback operated machine pistol developed by Gordon B. Ingram in 1964. It is chambered in either .45 ACP or 9mm. A two-stage suppressor by Sionics, was designed for the MAC-10, which not only abated the noise created, but made it easier to control on full automatic.

Design

The M-10 was built predominantly from steel stampings. A notched cocking handle protrudes from the top of the receiver, and by turning the handle 90° would lock the bolt, and act as an indicator that the weapon is unable to fire. The M-10 has a telescoping bolt, which wraps around the barrel. This allows a more compact weapon, and balances the weight of the weapon over the pistol grip where the magazine is located. The M-10 fires from an open bolt, and the light weight of the bolt results in a rapid rate of fire. In addition, this design incorporates a built in feed ramp as part of the trigger guard (a new concept at the time) and to save on cost the magazine was recycled from the M3 Grease Gun. The barrel is threaded to accept a suppressor, which worked by reducing the discharge’s sound, without attempting to reduce the velocity of the bullet. At the suggestion of the United States Army, it also acted as a foregrip to inhibit muzzle rise when fired. Ingram added a small bracket with a small strap beneath the muzzle to aid in controlling recoil during fully automatic fire. The original rate of fire for the M-10 in .45 is approximately 1090 rounds per minute. That of the M11/nine 9mm is approximately 1250 rounds per minute, and that of the M11 .380 is 1380 rounds per minute.

Suppressor

The primary reason for the original M-10 finding recognition was its revolutionary sound suppressor designed by Mitchell Werbell III of Sionics. This suppressor had a two-stage design, with the first stage being larger than the second. This uniquely shaped suppressor gave the MAC-10 a very distinctive look. It was also very quiet, to the point that the bolt could be heard cycling, along with the suppressed report of the weapon’s discharge; however, only if subsonic rounds were used. The suppressor when used with a Nomex cover created a place to hold the firearm with the secondary hand, making it easier to control. During the 1970s the United States placed restrictions on the exportation of suppressors, and a number of countries canceled their orders of M-10s as the effectiveness of the MAC-10’s suppressor was one of its main selling points. This was one factor that led to the bankruptcy of Military Armament Corporation, another being the company’s failure to recognize the private market. The original Sionics suppressor is 11.44 inches in length, 2.13 inches in overall diameter, and weighs 1.20 pounds.

Nomenclature

The term “MAC-10” is commonly used, but unofficial, parlance. Military Armament Corporation never used the nomenclature MAC-10 on any of its catalogs or sales literature, but because “MAC-10” became so frequently used by Title II dealers, gun writers, and collectors, it is used more frequently than “M10” to identify the gun.

Calibers and Variants

While the original M-10 was available chambered for either .45 ACP or 9mm, the M-10 is part of a series of machine pistols, the others being: the MAC-11 / M-11A1 semi, which is a scaled down version of the M-10 chambered in .380 ACP; and the M-11/9, which is a modified version of the M-11 with a longer receiver chambered in 9mm, later made by SWD (Sylvia and Wayne Daniel), Leinad and Vulcan Armament.

In the United States, machine guns are National Firearms Act items. As Military Armament Corporation was in bankruptcy large number of incomplete sheet metal frame flats were given serial numbers then bought by a new company, RPB industries. Some of the previously completed guns (already stamped MAC), were stamped on the other side RPB, making a “double stamp” gun.

RPB Industries made many open-bolt semi-automatic and sub-machine guns before the Bureau of Alcohol Tobacco and Firearms (abbreviated ATF) seized roughly 200 open bolt semi autos during the drug wars of 1981. ATF insisted that all future semiautomatic versions were to be manufactured with a closed-bolt design as the open-bolt semiautomatics were considered too easy to illegally convert to full automatic operation.

Wayne Daniel, a former RPB machine operator, purchased much of their remaining inventory and formed SWD, designing a new weapon which was more balanced, available either fully or semi-automatic with his new ATF approved closed bolt design.

There are several carbine versions of the M-11/9 and Cobray and SWD manufactured a smaller version chambered in .380 ACP as a semiautomatic pistol called the M-12.

Today, while the civilian manufacture, sale and possession of post 1986 select-fire MAC-10 and variants is prohibited it is still legal to sell templates, tooling and manuals to complete such conversion. These items are typically marketed as being “post-sample” materials for use by Federal Firearm Licensees for manufacturing/distributing select-fire variants of the MAC-10 to Law Enforcement, Military and Overseas customers.

The Sass

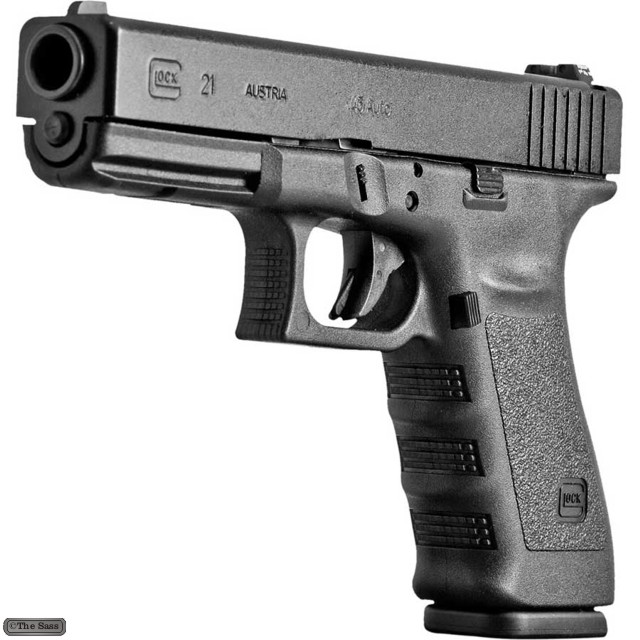

Glock 21

Remarkable for its accuracy and light recoil, the GLOCK 21 delivers the legendary stopping power of the .45 AUTO round with a 10/13 round magazine capacity. Countless law enforcement units swear by the G21 pistol, and that’s why this powerful, lightweight, all climate workhorse is standard issue from the North to South Poles.

Glock pistols chambered for the .45 ACP feature octagonal polygonal rifling rather than the hexagonal shaped bores used for models in most other chamberings. Octagonal rifling provides a better gas seal in relatively large diameter rifled bores, since an octagon resembles a circle more closely than a hexagon.

The Glock 21 is a .45 ACP version of the Glock 20 designed primarily for the American market. Compared to the Glock 20 chambered in 10mm Auto, the slide of the Glock 21 is lighter to compensate for the lower-energy .45 ACP cartridge. The standard Glock 21 magazine is of the single-position-feed, staggered-column type with a capacity of 13 rounds.

The Glock 21SF is a version of the Glock 21 that utilizes the Short Frame (SF) which is based on the standard G21 frame (same width), but reduces the trigger reach from the back of the grip by 2.5 mm (0.098 in) and the heel of the pistol is shortened by 4 mm (0.16 in) so the trigger can be reached and operated better by users with relatively small hands.

The Sass

Para-Ordnance P14-45

Para USA (Para) is an American-owned firearms manufacturer. It is the successor to Para-Ordnance, founded in Canada in 1985. It specializes in making M1911-style semi-automatic pistols.

History

Para-Ordnance was founded in Canada, in 1985, by two childhood friends, Ted Szabo and Thanos Polyzos. Szabo was born in Hungary and his family fled the country when the Soviets invaded during the Hungarian Revolution in 1956. Polyzos was born in Greece and later emigrated to Canada. On March 28, 2007, Ted Szabo died at the age of 60. The company’s first product was a plastic paintball gun, the Model 85 “Dye Marking Tactical Machine Pistol”, designed for police and military training purposes.

Para-Ordnance had a factory in Scarborough, Ontario, Canada. The company was estimated to have an annual revenue of over 10 million dollars and employs a staff of 60.

In January 2009, it was announced that the U.S. headquarters for Para-Ordnance’s U.S. subsidiary (Para USA) would be set up in Pineville, North Carolina. In January 2012, Para-USA became a part of the Freedom Group, owned by Cerberus Capital Management.

Products

Para-Ordnance was the originator of a high magazine capacity M1911-style pistol. Para-Ordnance was also the manufacturer of the first double-action-only 1911-style pistol. The company has created a true double-stack 1911 pistol, in addition to single- and double-stack pistols in .45 ACP, .40 S&W, 9 mm, and .38 super calibers. Para pistols have found a variety of uses, including competition, law enforcement, concealed carry, and general barrier shooting. The introduction of the LDA (Light Double Action) allowed law enforcement agencies to use 1911-style pistols while still addressing the perceived liability issues of a single-action pistol.

The Sass